In 2021, Montgomery & Associates (M&A) published a Hydro Note on lithium brine exploration and extraction. Since then, an increasing number of lithium brine projects in salt flats (salars) have been in development. According to the Argentina Government database (2024) [1], only 16% of lithium projects in Argentina are at a construction or production level, signifying that a majority of the projects are due to advance to eventual production. The Chilean Government has also expressed increased interest in the development of lithium brine projects through international collaboration and special contracts to explore for and extract lithium [2]. Mining projects at these advanced stages often require Qualified Persons (QPs) who have the education and relevant experience to ensure that scientific and technical information is appropriately generated and accurately reported. In 2024, 3 M&A QPs –Brandon Schneider, Megan Zivic, and Mike Rosko–gave a lithium brine short course at the Prospectors & Developers Association of Canada (PDAC) Conference and are providing lithium modeling and wellfield services to develop reconciliation programs for clients’ advanced lithium brine projects transitioning to production.

Defining Reconciliation for Lithium Brines

Reconciliation is the process of identifying, analyzing, and managing the variation between planned and actual production results to improve mine performance [3]. In general, reconciliation is frequently recommended for prudent, timely, and informed management decisions, and it can be beneficial for long-term planning.

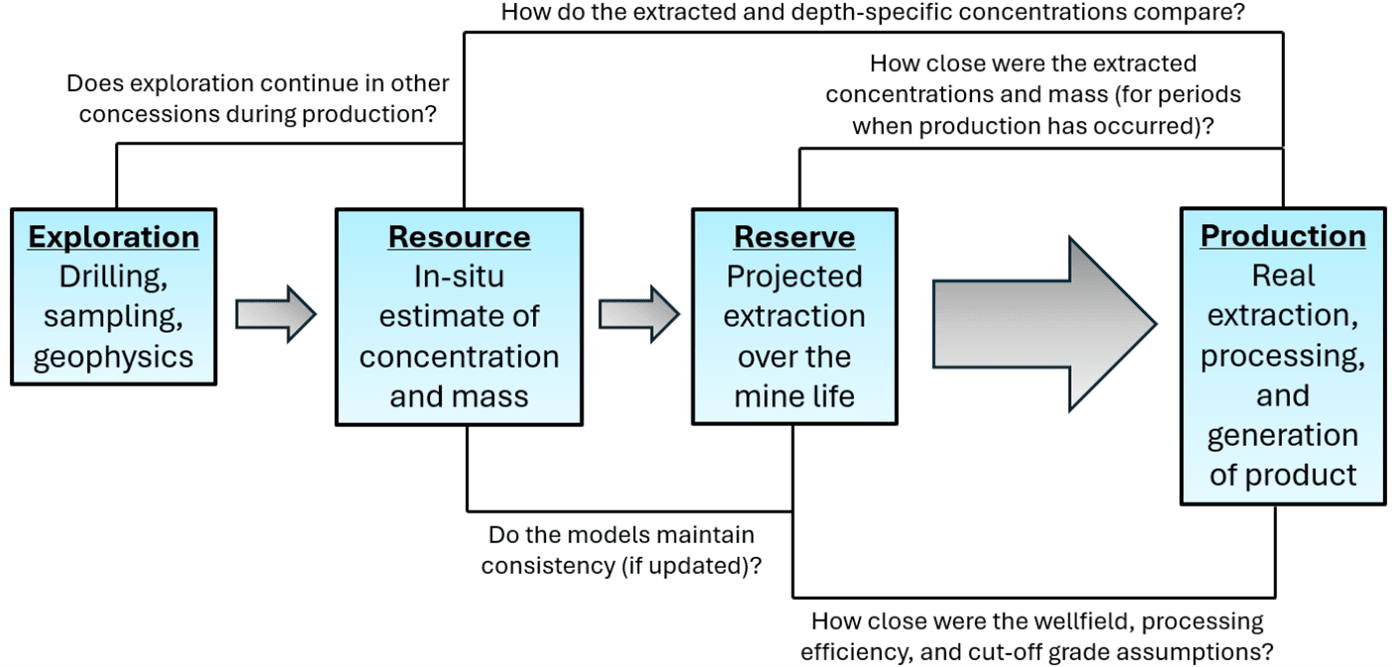

Compared to traditional (solid) deposits, lithium brine reconciliation is challenging due to the mobilization of brine once wellfield pumping begins. Figure 1 presents typical milestones for lithium brine projects where a reconciliation effort can involve various elements when entering production, such as the following:

- Comparing real production to simulated production in the existing groundwater flow and solute transport (reserve) model, with subsequent adjustments or “recalibration”

- Further review of the reserve model once production begins, and in particular, the average lithium concentrations

- Review of the processing and cut-off grade assumptions used for the reserve estimate

The specific management of mine performance will depend on the salt flat grade distribution and aquifer parameters, unique considerations for wellfield management, and processing methodology.

Figure 1: General Project Steps and Questions Related to Reconciliation

Challenges and Considerations for Operational Projects

Key common challenges and considerations for projects entering or in production include the following:

- Assessing the composite grade of brine entering the processing plant against depth-specific measured concentrations from individual wells

- Reconciling annual production in a dynamic setting against previously reported Reserves for annual reporting and long-term planning

- Monitoring drawdowns to thresholds for environmental compliance and assessing any mitigative actions

- Accounting for long-term mass migration as the brine is mobilized due to pumping or potential dilution from reinjection or spent brine ponds

- Evaluating freshwater availability and quality depending on processing advancements

- Accounting for pumping from any adjacent operations

- Wellfield management for optimal performance, well performance assessments to verify current well capacities, and well rehabilitation programs to prolong the life of wells

Each of these considerations involves updating initial models to integrate new well data, maintaining the tool to assess continual production, or running predictive simulations to assess future conditions.

Data Capture and Reconciliation Strategy

Apart from natural hydrogeological processes in salt flat environments which can induce mixing, brine mobilizes more rapidly once wellfield pumping begins. This mobilization results in a reconfiguration of the mass distribution over time and eventual changes in the extraction rate if a well’s capacity degrades. Only a few lithium brine projects have evaluated reconciliation versus years of production or against a ramp-up phase of their initial production schedule. Thus, as more lithium brine projects advance, reconciliation will be increasingly important for subsequent reserve reporting and long-term planning.

In the lithium brine industry, early-stage projects typically characterize lithium grade for the resource estimate using exploration well samples representing a specific or small depth interval. When moving to a reserve estimate, brine samples from short- and long-term pumping tests demonstrate temporal trends of grade and extractability of the brine, and samples represent a composite or average concentration over the entire screened interval of the pumping well. Composite sampling provides confidence in the brine profile and maturity of the deposit. Continuing with depth-specific samples may be impractical when in production, so the use of composite samples provides a more realistic determination of the average brine grade for processing purposes.

A routine well monitoring program is required and more practical for assessing intermittent production plant and wellfield management, future Ore Reserves, and production reconciliation. A program such as this should include routine collection of composite brine samples at production wells, with the corresponding quality assurance-quality control measures and regular measurements of water levels and pumping rates. Monitoring programs should also include more distal observation wells for brine/water levels and a characterization of the freshwater-brine interface to evaluate changes with production.

Reconciliation will require periodic reserve model updates as the mine life decreases to incorporate measured time-series data from the production wells, any changes in well capacities, well monitoring program, evaporation measurements, precipitation, reinjected spent brine or infiltration from evaporation ponds, and monitoring from environmentally sensitive sites. Model behavior will be assessed against the measured data and, if necessary, recalibration of the reserve model will result in parameter adjustments to ensure that subsequent projections are adequate. Compared to an initial reserve, the calibration effort from production reconciliation may focus on an extended transient calibration to collective pumping, rather than individual pumping tests. Furthermore, depending on how the resources are reported (inclusive or exclusive of reserves), previously categorized resources could be reevaluated where confidence has increased due to demonstrated pumping and production.

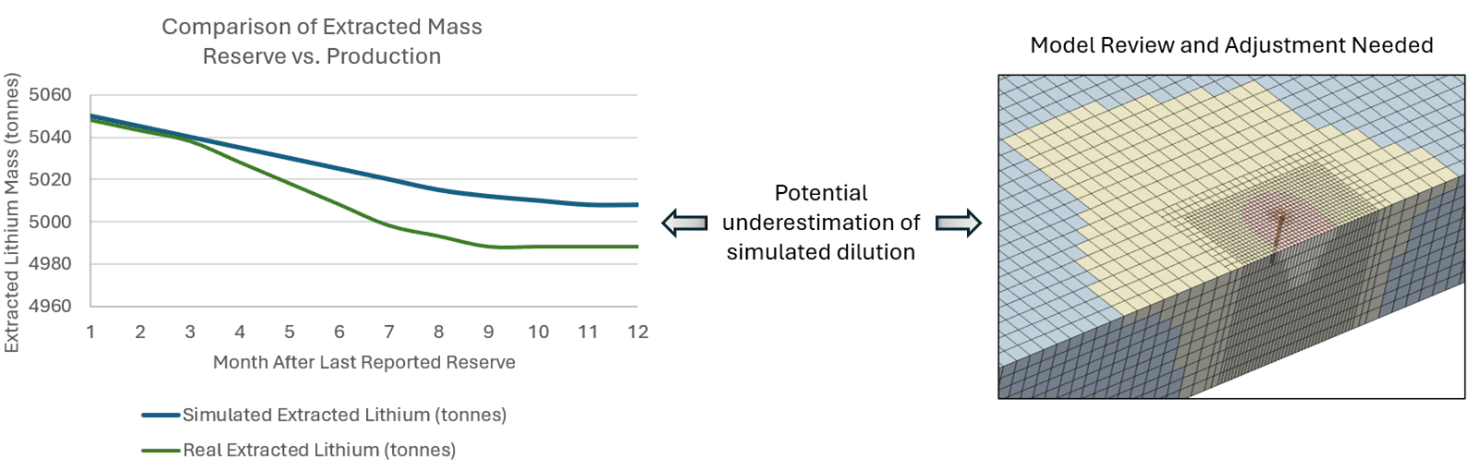

Figure 2 illustrates the overall process by which a lithium brine reserve model could be updated depending on the comparison of simulated and real production; in this example, a reserve model overpredicted extracted mass when compared to real production (during the same year). Model differences should be carefully evaluated for subsequent projections.

Figure 2: Reconciliation of the Reserve Model Using Production Data

Final Thoughts

Lithium brine extraction is a growing industry with unique challenges. Robust programs and procedures are needed for future reconciliation due to the mobile nature of the brine. Variances from prediction to production may be high as wellfield and processing plant management issues are resolved at the start of the mine life. Furthermore, the reported resources and reserves from initial modeling may need to be closely evaluated against real production data. As more lithium brine projects advance to production, M&A is at the forefront of evaluating these best practices and is also helping clients during the process.

References

[1] Secretaría de Minería de Argentina (2024). Litio, Argentina como jugador estratégico en el mercado global (p. 21) https://www.argentina.gob.ar/sites/default/files/presentacion_litio_2024_2.pdf

[2] Ministerio de Economía, Fomento y Turismo de Chile (2024). Estrategia Nacional del Litio: Gobierno anuncia apertura de proceso para asignar CEOLes en seis yacimientos de litio. https://www.economia.gob.cl/2024/12/05/estrategia-nacional-del-litio-gobierno-anuncia-apertura-de-proceso-para-asignar-ceoles-en-seis-yacimientos-de-litio.htm

[3] Morley, Craig, and Hargreaves (2014). Mining Reconciliation – an overview of data collection points and data analysis. Mineral Resource and Ore Reserve Estimation – The AusIMM Guide to Good Practice – Second Edition. Monograph 30. 739.

About the Authors

Brandon Schneider, P.G. RM-SME, is a Senior Hydrogeologist and Qualified Person in M&A’s Santiago, Chile, office who specializes in the dynamic modeling of lithium brines.

Megan Zivic, P.G. RM-SME, is a Principal Hydrogeologist and Qualified Person in M&A’s Tucson, Arizona, office who specializes in lithium brine resource modeling and geological modeling.